San Antonio, TX, USA, July 27th, 2017

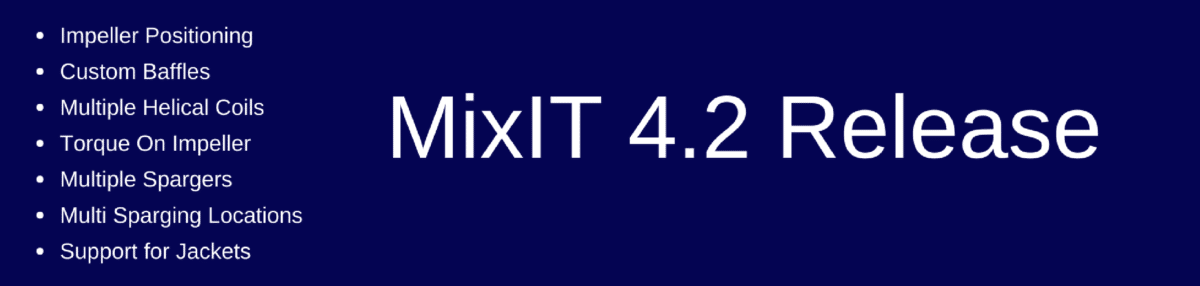

Tridiagonal Solutions Inc. is pleased to announce the release of MixIT 4.2, a unique tool designed to evaluate stirred tank mixing. MixIT helps in analyzing and predicting the mixing process using advanced 3D CFD models and empirical correlations. It provides insights to solve scale-up problems and reduce uncertainties during tech transfer. The intuitive and streamlined interface facilitates chemists and process engineers to quickly analyze multiple scenarios to optimize the mixing performance.

MixIT 4.2 offers flexibility in impeller positioning. The impellers can be placed and angled along the tank circumference allowing users to simulate tank geometries.

MixIT 4.2 introduces variability in handling baffles and a facility to import their custom-made baffles.

MixIT 4.2 allows users to simulate tanks with multiple helical coils for complex temperature sensitive processes.

MixIT 4.2 enables the user to plot torque on impeller during run time simulation.

MixIT 4.2 offers flexibility to select multiple sparging locations for gas dispersion analysis.

MixIT 4.2 offers support for specifying side and bottom jacket details separately.

Click here to know more about MixIT.

Tridiagonal Solutions Inc is an advanced engineering solutions provider with expertise in process performance enhancement and product development solutions for industrial clients worldwide. Their portfolio includes process engineering, CFD, EFD, Discrete Element Modeling services and chemical mixing simulation products . Tridiagonal Solutions caters to the Chemical and Process, Oil and Gas, Consumer goods, Food, Electronics, Power Generation and Healthcare Industries. For more information please visit www.tridiagonal.com or call (210) 858-6192.

Tridiagonal Solutions Inc | 12703 Spectrum Drive | San Antonio | TX 78249 | USA

newsletter-mixit@Tridiagonal.com

Leave A Comment