Leverage Mixing Analysis for Right-first-time Scale-up Success

- Save to Calendar

- 18/04/2024 - 10:00 am - 11:00 am GMT

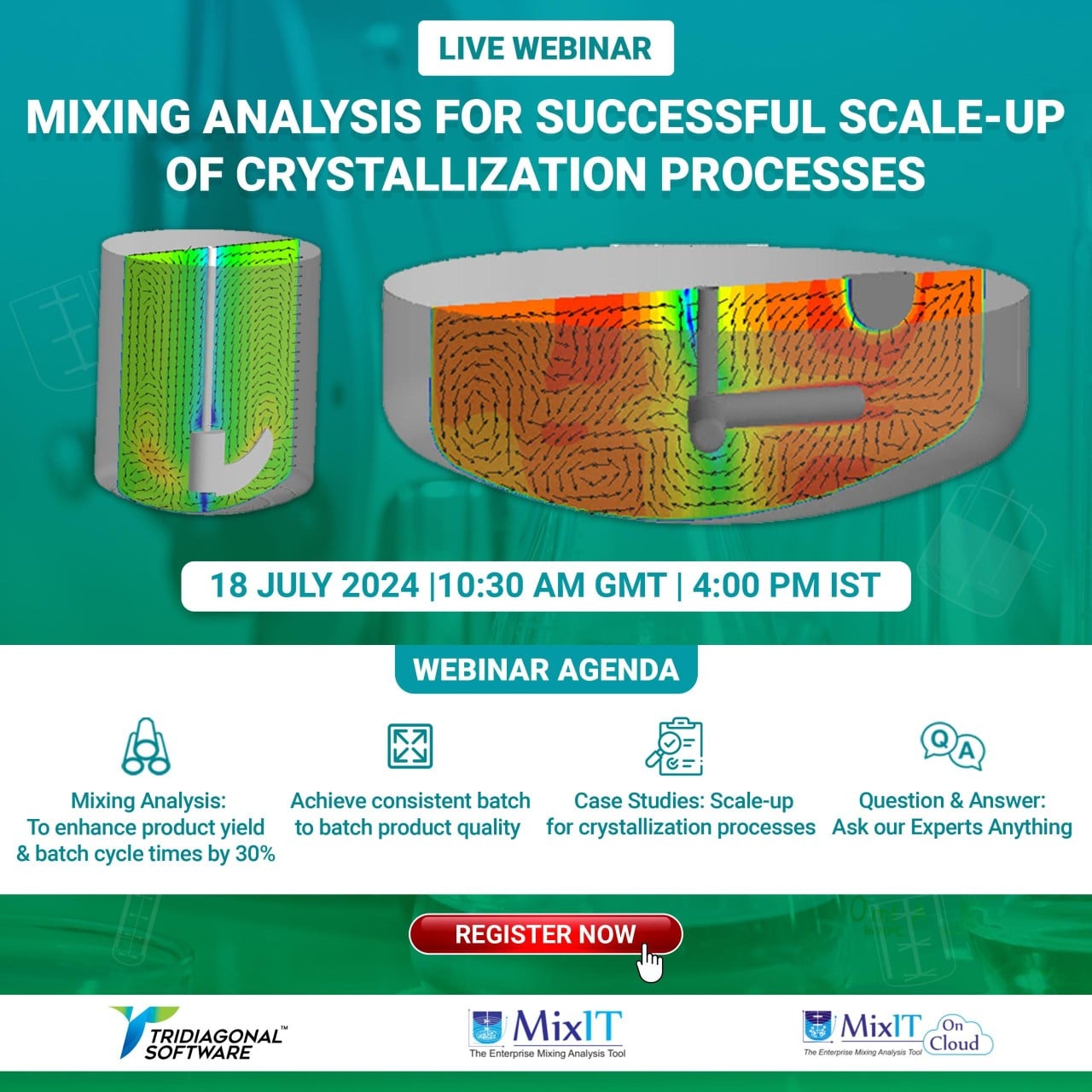

Scale-up of chemical processes such as mixing sensitive reactions and crystallization processes in stirred tank reactors can many times go wrong due to the limitations of mixing correlations such as mismatched geometric similarity and experimental conditions under which the correlations are applicable.

A user-friendly CFD-based software MixIT allows a process engineer to accurately calculate and compare mixing parameters across the scales and select the most appropriate reactor and/or implement necessary changes in the agitator design, identify the most suitable dosing location to replicate the mixing environment from lab/ pilot plant to production scale.

This webinar shares case studies of mixing scale-up for a liquid-liquid heterogeneous fast oxidation reaction, a low occupancy antisolvent crystallization process to replicate particle size, selection of dosing location in an antisolvent crystallization process to improve particle size and hence filtration time and site-to-site process transfer for a liquid-liquid heterogeneous reaction. The selection of mixing scale-up parameters and use of three-dimensional analysis of velocity, turbulent energy dissipation rates and calculation of droplet size distribution and mesomixing time distribution is demonstrated in the case studies to ensure successful scale-up.

Register Now

The webinar either no longer exists or an error has occured.