Intuitive GUI

The intuitive GUI makes it easy to enter geometric details such as tank dimensions, bottom shapes, baffle details, internals such as dip tubes or coils, specify liquid, gas or solid properties, and process parameters such as shaft speed, temperature and pressure.

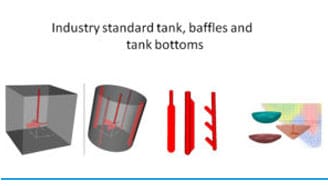

Industry Standard Bottom Shapes

Extensive Impeller Library

The built-in library includes standard impellers such as pitched blade turbine, rushton turbine, anchor agitators. The library is easily extended to import impellers from specific vendors like Chemineer, Lightnin mixers and others. Users can also create and import their own impellers.

Flexibility In Impeller Positioning

Top entering impellers can be inclined at any angle and placed anywhere in the tank by using the X-Offset and Y-Offset functionality. The horizontal impellers can now be positioned anywhere along the circumference of the tank and inclined at an angle. Allowing users to simulate tank geometries involving multiple side entering impellers and bottom mounted angled impellers.

Baffles

MixIT users can select from a range of baffle types such as Standard Flat, Fin, Beavertail, Flattened Pipe, h-style etc. Users can easily change the number, dimensions and placement of baffles.

Custom Baffles

Users can now use a combination of different types of baffles and place them anywhere in the tank. MixIT also allows users to import their custom made baffles into MixIT for CFD analysis.

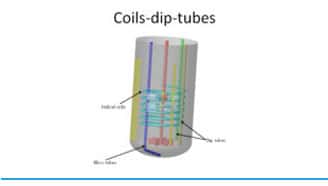

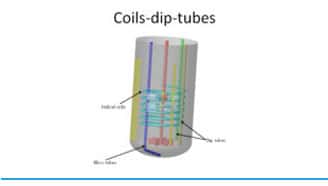

Spargers, Coils and Dip Tubes

Users can quickly create various internals like Ring Spargers, Coils, Dip Tubes and locate them appropriately in the reactor by entering various dimensions and parameters. Multiple dip-tubes can be specified simultaneously.

Spargers And Coils

MixIT 4.2 can now accommodate even more complex tank internals. MixIT allows users to simulate tanks with multiple helical coils for complex temperature sensitive processes. Heat transfer calculations in MixIT are now even more accurate as MixIT accounts for the side jacket as well as the bottom jacket. For large multiphase systems, MixIT allows users to specify multiple spargers.

Correlation Based Analysis & Performance Comparison

MixIT users can get preliminary predictions of reactor performance using empirical correlations with respect to various parameters such as power per unit volume, blend time, gas hold-up, mass and heat transfer characteristics, critical impeller speed for solids suspension and many more. Users can also quickly compare performance of reactors across scales for a given process.

Customizable Correlations

MixIT allows users to analyze the reactor performance using their own correlations. User can quickly create their own correlations using various input variables. User can share the correlations among themselves using import and export features.

Fully Automated 3D CFD Analysis

Perform fully automated 3D steady state, single phase flow analysis of stirred reactors. The CFD models can calculate performance parameters such as velocity fields, shear rate distribution, flow patterns in the reactor. The CFD models can also perform heat transfers and mixing analysis.

Runtime Monitor Plots

Powerful Reports and Visualization tool

MixIT generates html reports with graphical and numeric data. Various graphical results such as contours and vector plots are generated from the CFD results along with animations to show the mixing profiles in the reactor. Various performance parameters such as, power and flow number, power consumption, blend time, mixing intensity, mass transfer coefficients are also calculated.

Tagging Reactor Types, Configurations and Processes

MixIT allows users to tag reactors a sitename and scale (lab/pilot/plant) along with its name. This makes it easy for the user’s to find the reactor quickly in the MixIT database.

Off-Centered, Angled and Multi-shaft Agitators

MixIT allows users to specify and do CFD analysis of the reactors with off-centered, angled and multi-shaft agitators. Along with this impeller speed and direction of rotation is specified for particular impeller.

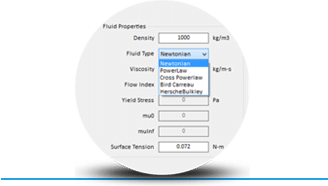

Fluid Rheology

Users can specify both Newtonian and non-Newtonian fluid rheology. Various non-Newtonian models such as Power Law, Cross Power Law, Bird-Carreau, Hersche-Bulkley are available to select from.

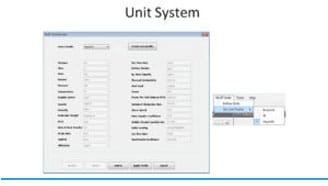

Flexibility of Unit System

MixIT gives flexibility to the users to input quantities in various units. Users can also change the unit system as and when required.

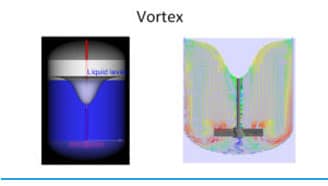

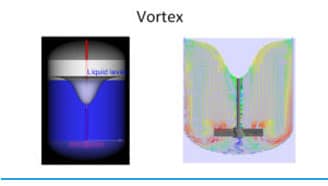

Vortex Shape Predictions

MixIT predicts vortex shape and vortex depth for top-mounted, centrally located impeller under fully un-baffled conditions. The predicted vortex shape can then be used (instead of flat top surface) while performing CFD analysis.