San Antonio, TX, USA, June 8th, 2016

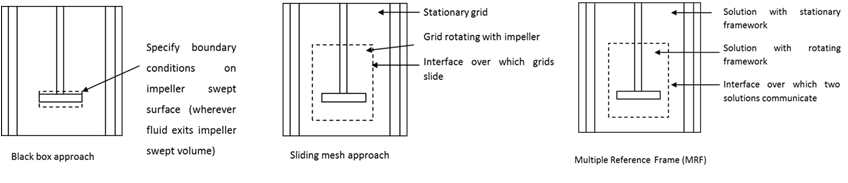

Despite the widespread use of stirred vessels, the relationship between fluid dynamics and hardware is not adequately understood. Simulating flows in the stirred vessels using Computational Fluid Dynamics (CFD) based models can provide a great insight into the mixing performance of the vessel. In stirred vessels the relative motion between the stationary baffles and the rotating impeller blades makes the complete simulation of the flow field in stirred reactor computationally awkward. Three types of approaches (Figure – 1) are proposed to model the flow generated by a rotating impeller in the reactor:

• Black Box Approach

• Sliding Grid Approach

• Multiple Reference Frame (MRF)

Figure – Impeller Modeling Approach. Please click on the image to expand.

In Black Box Approach the impeller region is excluded from the computational domain. This approach requires the specification of the impeller boundary conditions (mean velocities and turbulent characteristics) on the impeller swept surface, which need to be determined experimentally. Although, this approach is reasonably successful in predicting the flow field in the bulk of the reactor, its usefulness is inherently limited. Few main weak points of this approach are listed below:

• The numerical simulations using this approach can be extended, at best, to geometries similar or close to that for which the experimental data is available.

• The flow field near the impeller blades depends on the overall tank geometry, so that the impeller cannot be uniquely characterized.

• Extension of this approach to multi-phase flows and to industrial scale reactor is not feasible because it is virtually impossible to obtain accurate boundary conditions

In Sliding Grid approach, two domains are fixed to the respective frames of reference, the outer one being stationary and the inner one is rotating with impeller. At the interface, the mesh was allowed shear and/or slide to accommodate the relative motion. The detailed geometry of the impeller needs to be modeled: impeller blades are modeled as solid rotating walls. The flow within the impeller blades is solved using the usual transport equations. The sliding mesh approach has the potential to generate ‘a priory’ prediction without requiring any experimental input. It can therefore be used as a design tool to screen different configurations. However, following considerations make the sliding mesh approach less attractive:

• It relies on the solution of the full time varying flow in a reactor. This increases the computational requirement by an order of magnitude compared with the steady state simulations.

• Excessive computational requirement put the restrictions on the computational grids used for the simulation of the flow. Such limitations may make predictions of the flow characteristics such as turbulent kinetic energy dissipation rate, shear rates near impeller blades etc. less accurate.

In MRF approach, the whole reactor is divided into two regions: an inner region attached to the rotating impeller and shaft and an outer region attached to the stationary baffles and the reactor. The model equations for the inner region are solved using a rotating framework, whereas the equations for the outer region are solved using stationary framework. The solutions from both regions are matched at the interface between the rotating and stationary region via velocity transformation from one frame to the other. This velocity-matching step implicitly involves the assumption of the steady flow conditions at the interface. Two approaches are available for modelling the communication between two regions (Marshall et al., 1996). In the first approach, the flow characteristics are circumferentially averaged at the interface and then used as boundary condition for the other region. However, in the second approach, no averaging is carried out and the continuity of absolute velocity is forced to provide the neighboring values of velocity for the region under consideration.

For most engineering applications, knowledge of the full time varying flow field (which becomes cyclically repeating after certain number of impeller rotations) may not be necessary. The flow simulation based on steady state simulation using MRF approach provides sufficient information to understand mixing performance of the stirred vessels.

Tridiagonal Solutions Inc is an advanced engineering solutions provider with expertise in process performance enhancement and product development solutions for industrial clients worldwide. Their portfolio includes process engineering, CFD, EFD, Discrete Element Modeling services and chemical mixing simulation products . Tridiagonal Solutions caters to the Chemical and Process, Oil and Gas, Consumer goods, Food, Electronics, Power Generation and Healthcare Industries. For more information please visit www.tridiagonal.com or call (210) 858-6192.

Tridiagonal Solutions Inc | 12703 Spectrum Drive | San Antonio | TX 78249 | USA

newsletter-mixit@Tridiagonal.com

Reference Links:

Leave A Comment