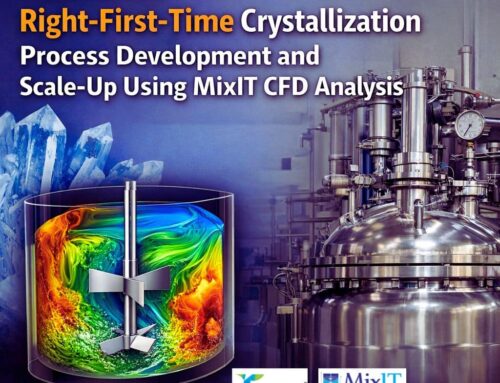

MixIT 2.0 Release featured flow pattern in Glass-lined Reactors with Glass-lined Impellers and various Baffle shapes.

San Antonio, TX, USA, March 26th, 2014

Tridiagonal Solutions Inc, a provider of advanced process engineering solutions announced the release of MixIT 2.0, the enterprise software to predict stirred tank mixing performance, with a unique capability of automated CFD analysis. MixIT 2.0 release provides flow pattern in glass-lined reactors incorporating glass-lined impellers and various baffle shapes (finger, beavertail, flattened pipe, etc) mounted from nozzle to the top head.

Following are the MixIT 2.0 cutting-edge added features:

- Multiple shapes of various baffles and availability to create geometry by providing details

- Added Impellers like : RCI, CBT, PBT, A310, A510

- More handles for CFD analysis

About MixIT

MixIT, a comprehensive, easy-to-use enterprise analysis software designed to predict stirred tank performance, with a unique capability of automated CFD analysis. MixIT enables enterprises to design, compare, scale-up (plant to lab scale) and analyze performance of multiple stirred tank reactors and bioreactors, by using standard correlations and advanced CFD models.

About Tridiagonal Solutions Inc

Tridiagonal Solutions Inc is an advanced engineering solutions provider with expertise in process performance enhancement and product development solutions for industrial clients worldwide. Their portfolio includes process engineering, CFD, EFD, Discrete Element Modeling services and chemical mixing simulation products . Tridiagonal Solutions caters to the Chemical and Process, Oil and Gas, Consumer goods, Food, Electronics, Power Generation and Healthcare Industries. For more information please visit www.tridiagonal.com or call (210) 858-6192.

Tridiagonal Solutions Inc | 12703 Spectrum Drive | San Antonio | TX 78249 | USA

newsletter-mixit@Tridiagonal.com

Follow Us On:

Reference Links:

Leave A Comment